Energy

Energy

Energy and humans are multifaceted and fundamental to human civilization. Humans rely on various forms of energy to meet their basic needs and to support economic and social activities. This includes energy for heating, cooling, lighting, transportation, industrial processes, and communication. Energy should be used responsibly for sustainability, reducing environmental impact, and ensuring a reliable energy supply for present and future generations. Arbon is with energy conservation and green energy, aimed promoting sustainability and reducing the environmental impact of energy production and consumption. Arbon’s energy conservation strategies focus on reducing overall energy consumption, while the Arbon’s green energy focuses on shifting to renewable and low-carbon energy sources.

1. Arbon Energy – The sustainable

Arbon’s renewable energy production involves generating electricity and/ or heat from naturally replenished sources like sunlight, wind, and geothermal heat on a human timescale. Arbon involves identifying and assessing potential sources of renewable energy in your given area. Arbon start the study by investigating the various renewable energy options present in your area. The sources Arbon evaluates include solar, wind, and biomass energy, identify the most plentiful and feasible resources for energy generation in your region considering factors like weather, terrain, and local laws.

Arbon evaluates the solar potential of your area considering sunlight availability, shading, and roof orientation. Analyzes wind speed and direction data to assess wind resources in your region by utilizing the wind maps and tools to pinpoint suitable locations for wind energy production. Arbon evaluates biomass availability by assessing organic materials sources. Arbon often collaborate with local stakeholders and government agencies to gather data and assess renewable energy project viability. Through this systematic assessment and exploration of renewable energy resources, Arbon helps transition towards a sustainable energy future.

Arbon Glare and Helios

Arbon Solar systems captures sunlight and converts it into electricity or heat.

The Arbon Glare solar system convert sunlight into electricity using PV semiconductor materials, while the Arbon Helios solar thermal systems concentrate sunlight to heat water or generate steam for powering turbines.

Arbon Zephyr and Aura

Arbon Wind systems harnesses the kinetic energy of wind to generate electricity where the wind velocity is high enough. The Arbon Zephyr horizontal axis wind turbine systems, and the Arbon Aura vertical axis wind turbine system is adopted based on wind availability and wind velocity.

Arbon Bio

Arbon evaluate the accessibility of biomass by examining nearby organic sources like agricultural leftovers, forestry byproducts, and municipal trash and analyze the feasibility and durability of biomass materials for generating energy, taking into account aspects like transportation and environmental effects. Arbon Bio systems produces biogas through anaerobic digestion to produce combination of methane and carbon dioxide to serve various application in industries like heating, boilers, generating electricity, or as a fuel for transportation.

Arbon Hybrid

Arbon combines multiple renewable energy sources in hybrid renewable systems to improve reliability, efficiency, and energy output. For instance, by pairing Arbon Glare with battery storage and Arbon Aura, a more stable and consistent power supply can be achieved through the utilization of complementary energy sources.

2. Arbon Capture – The recovery

The Arbon Capture solution involves capturing and reusing waste heat and other types of energy produced during industrial processes to enhance energy efficiency, cut costs, and lessen environmental effects. Arbon adopts the below strategies to capture waste energy from the industries. Arbon designs and build desuperheater heat exchangers and heat pumps to capture waste heat from hot exhaust gases to pre-heat water or air, increasing overall energy efficiency of boilers, under floor heating etc.

Cogeneration systems simultaneously produce electricity and useful heat from a single fuel source, such as natural gas, biomass, or waste heat from industrial processes. By capturing and utilizing both electricity and heat, cogeneration systems can achieve high overall energy efficiency compared to separate generation of electricity and heat. Arbon builds thermal energy storage systems for industries to store excess heat generated during off-peak hours and utilize it during periods of high demand. This helps to optimize energy use, reduce energy costs, and improve system flexibility and reliability. Arbon designs and build vapor absorption chillers and/ or adsorption chillers to utilize waste heat to provide cooling for industrial processes or air conditioning in buildings, reducing the need for electricity-powered cooling systems.

Arbon’s Capture recovery system in industries helps maximizing resource utilization, reducing energy costs, and minimizing environmental impact. By capturing and reusing waste energy, Arbon helps reduce the carbon footprint of industries, thereby improve their competitiveness, enhance sustainability, and contribute to global efforts to address climate change and resource depletion.

3. Arbon Optimizer – The enhancer

Arbon helps optimize energy of your industries, process plants, refrigeration and cooling plants, and manufacturing plants. Arbon Optimizer in industries involves implementing strategies and technologies to improve energy efficiency and reduce energy consumption in industrial processes. Arbon performs energy audits to analyze current energy usage, detect inefficiencies, and prioritize areas for enhancement. Energy audits involve studying energy consumption data, examining equipment and systems, and comparing energy performance to industry standards.

Arbon sets up energy management systems to oversee and improve energy usage in real-time. The utilization of EMS software and tools to pinpoint energy-saving possibilities, establish energy efficiency targets, and monitor progress. Arbon evaluates and upgrades to energy-efficient equipment, machinery, and technologies to replace old or inefficient systems and optimize industrial processes to decrease energy consumption while maintaining or increasing productivity. Arbon develops key performance indicators (KPIs) and energy performance metrics to measure and track energy efficiency enhancements. Arbon continuously evaluate the energy consumption, costs, and savings over time, using performance data to identify areas for further improvement.

For instance, our Energy optimizer for the Refrigeration systems optimizes the energy consumption of your system. It’s inbuild floating head pressure controller chooses optimum condensing pressure at every instance of operating and ambient conditions to further improve COP. It is based on ambient conditions by varying the amount of airflow through the condenser in order to prevent frozen evaporators, liquid-slugging in compressors, and low-pressure cut-outs. Rather than target a fixed head pressure setpoint during operation, a custom-designed algorithm within the FCP system has the ability to vary head pressure dependent on load and in some cases, ambient. Efficiency is optimized by balancing condenser fan and compressor power consumption, resulting in a maximized system EER while guaranteeing cooling duty.

Besides a head pressure optimization, the Volume Index optimization, Compression Ratio Optimization, and Evaporation Pressure optimization further optimizes the system based on heat load and ambient conditions. Typical energy savings using this ingenious control feature on precision products can be up to 23%. The energy monitoring feature in the PLC records the real-time energy consumption of the refrigeration system in its database. Its sophisticated algorithm calculates the Coefficient of performance and Energy Efficiency Ratio of the refrigeration system. It helps the engineers to optimize their system and also helps to find operation errors and condition of refrigeration machines in a very earlier stage.

Glimpse of Energy Auditing

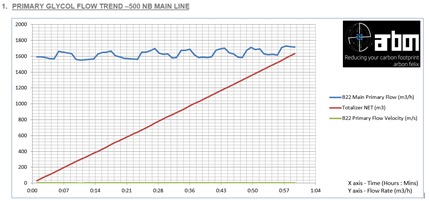

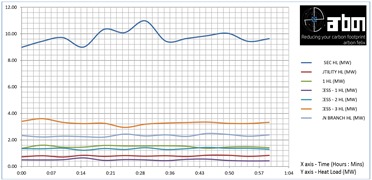

Glimpse of Flow Measurement and Energy Analysis

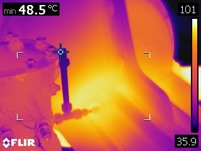

Thermal Imaging of Control Panels

Thermal Imaging of Compressors

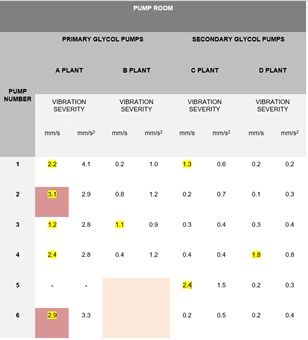

Vibration Analysis

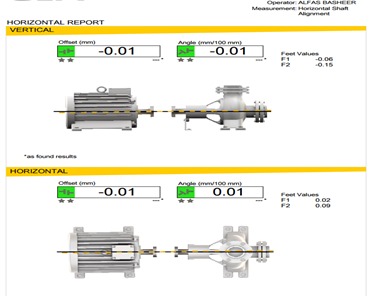

Machine Alignment