Water

water

Water is essential for life on our planet. With the increasing demand for water and the limited supply, it has become crucial to conserve and utilize the available resources efficiently. Water conservation is a pressing issue that requires collective efforts from individuals and communities. Arbon implements effective strategies, we can help optimize water usage, conserve resources, and ensure the sustainable management of the water resources. Let us help you to play our part in conserving water for the benefit of present and future generations. 🌍💧

- Sustainability: ensure a sustainable water supply for future generations.

- Environmental Protection: minimize our impact on ecosystems and conserve valuable natural resources.

- Financial Savings: significant cost savings for both individuals and businesses.

Arbon’s key strategies for Water Conservation

- Use Efficiently: Use water for necessary applications.

- Reuse Graywater: Reuse greywater for irrigation, CIPs and/ or for utility applications instead of sending it down the drain.

- Reduce Water Consumption in Industries: Encourage industries to adopt water-efficient technologies and practices. Implement water recycling systems, monitor water usage, and adopt water-saving technologies.

1. C-Electro Treatment

Industrial equipment used in manufacturing and environmental control rely heavily on water to either cool, or otherwise regulate product or formulation temperature during processing. While such equipment can appear to function efficiently without input of truly pure water, the unknown cumulative build-up of scale and corrosion would be costly due to high maintenance, related damage, reduced efficiency, and ultimately, premature equipment failure.

Arbon’s C-Electro Treatment is a controlled partial electrolysis process of using electrolysis to selectively produce a desired product quality while minimizing the formation of unwanted byproducts. In water treatment, Arbon introduce partial electrolysis be used to remove impurities and contaminants from water through electrochemical reactions.

This is achieved by controlling various parameters such as voltage, current, electrolyte concentration, and electrode materials. Arbon C-Electro Treatment effectively controls the voltage and current applied to the electrodes, the duration of the electrolysis process, and monitors factors like pH and conductivity to ensure proper conditions for the desired reactions.

The reaction helps to oxidize organic compounds, kill bacteria, and remove certain metals from the water, minimizes scaling, reduces corrosion and removes impurities.

2. C-Electro-Chem Treatment

Industrial effluent from non-residential sources typically needs extra treatment steps before being released into the environment. Various industries like metal finishers, power plants, dairy plants, and breweries generate wastewater containing harmful chemical and biological contaminants that can harm the environment and human health. These pollutants must be eliminated before the water can be safely returned to the environment or used again in industrial processes.

Conventional methods involve the use of numerous chemicals to eliminate impurities. This can result in residual chemicals like chlorine in the water, altering its pH and rendering it unsuitable for specific purposes like farming. Expertise is necessary to add chemicals to the water, leading to increased costs due to the continual use of materials.

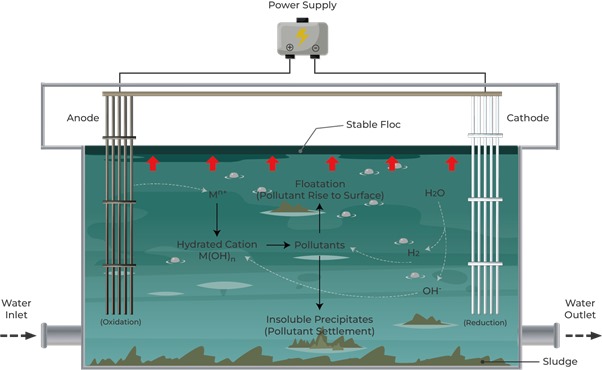

Arbon’s Electro-flocculation uses lesser amount of chemicals.

Arbon’s Electro-flocculation is a method that uses direct electrical current to treat contaminants that are hard to remove by filtration, combining electro-flotation and electro-precipitation processes. It can effectively remove suspended solids to sub-micrometer levels, breaks emulsions such as oil and grease or latex, and oxidizes and eradicates heavy metals from water.

Arbon Electro flocculation is very efficient. Depending on the cathode and anode materials chosen, the materials are cost-effective. Options for sacrificial anodes include magnesium, iron, and aluminum. Eventually, the sacrificial anode needs replacement. However, this process incurs lower operational expenses for staff and replacement materials when compared to alternative methods. Arbon electro flocculation serves as a pre-treatment for water prior to reverse osmosis. Furthermore, utilizing direct current electricity instead of alternating current electricity can lead to cost savings.

3. C-De-Watering

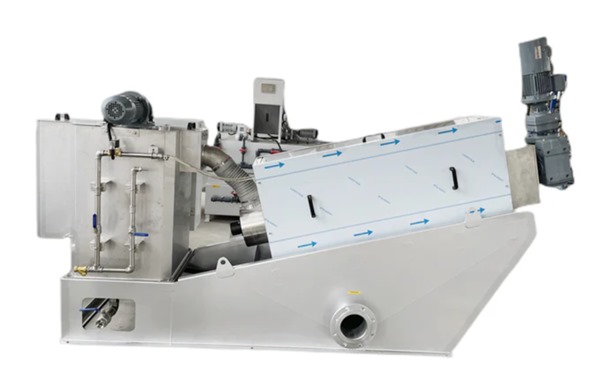

Arbon’s Sludge dewatering system eliminates excess water from sludge, a byproduct of slurry extraction in wastewater treatment. Arbon adopts belt press and/ or centrifuge for easier disposal, as sludge contains a high water content, making it heavier and costlier to dispose of. The liquid and solid components obtained from industrial and municipal wastewater treatment are separated, with the liquid being reused for industrial purposes. Strict global regulations ensure proper disposal of sludges or their conversion into dry powder using biodigesters.

The C-dewatering machine has a concentration section and a dewatering section. Once the sludge is thickened by gravity in the concentration section, it is moved to the dewatering section where the filter gap and screw pitch decrease. This creates internal pressure, reduces the sludge volume, and ensures complete dewatering.

Salient Design Features of C-De-Watering Machine

- A filtering device is formed by stacking fixed and moving rings with tie rods and a screw shaft.

- The filter gap and screw pitch decrease as you move from the concentration section to the dewatering section.

- The rotation of the screw shaft moves sludge from the concentration section to the dewatering section and cleans the filter gap to prevent clogging.

- Using the screw shaft, the concentrated sludge is moved to the dewatering section where internal pressure, along with a smaller filter gap and screw pitch, helps to dewater the sludge.

4. C-Aqua Optimizer

Arbon’s water optimization processes for industries involve strategies and technologies aimed at reducing water usage, minimizing wastewater generation, and improving overall water efficiency.

Some key approaches implemented by Arbon are

Water Audits and Monitoring: Arbon conducts regular water audits to identify areas of high-water usage and potential leaks. Install Arbon monitoring systems to track water consumption in real-time can also help in identifying inefficiencies.

Industries of C-Electro, C-Electro-Chem, C-Dewatering and C-Aqua Optimizer

- Municipal Sewage

- Food and Beverage Industry

- Slaughter and Breeding facility

- Printing and Dyeing Plants

- Petrochemical Industry

- Paper Manufacturing Plant

- Leather Industry

- Pharmaceutical Engineering

- Industrial Cooling and Heating Systems

Arbon implement process modifications to reduce water consumption. This involve using closed-loop systems, recycling and reusing water within the production process, and optimizing equipment and machinery for water efficiency.

Arbon continuously invests in water-efficient technologies such as low-flow fixtures, water-saving equipment, and advanced water treatment systems like installing high-efficiency cooling towers or adopting membrane filtration systems can significantly reduce water usage.

Arbon helps implement wastewater treatment processes to treat and recycle wastewater for reuse within the facility. Technologies such as reverse osmosis, biological treatment systems, and ion exchange are employed to treat wastewater to meet quality standards for reuse.

Arbon educates employees of client about the importance of water conservation and providing training on best practices for water efficiency.

: Arbon ensures compliance with local regulations and permits related to water usage, discharge, and wastewater treatment. Staying abreast of regulatory requirements and implementing measures to meet or exceed these standards is essential for sustainable water management.

Arbon conducts lifecycle assessments to evaluate the environmental impacts associated with water usage throughout the supply chain. This helps identify opportunities for improvement and guides decision-making towards more sustainable water practices.

Arbon collaborates with suppliers, customers, and other stakeholders to identify shared water challenges and develop collective solutions. Partnerships helps Arbon facilitate knowledge sharing, resource pooling, and joint initiatives to address water-related issues.

Arbon helps establish a framework for continuous improvement by setting water efficiency targets, monitoring progress, and regularly reviewing and updating water management strategies. Continuous improvement ensures that water optimization efforts remain effective and aligned with changing business needs and environmental conditions.